milling machine parts and functions ppt

Meaning of Milling Machine. It is used in Institutions or colleges to conduct lab tests on milling machine.

What Are the Parts of A Milling Machine.

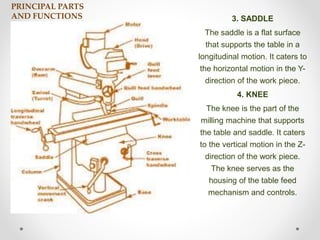

. The column contains an oil reservoir and a pump which lubricates the spindle. This machine can hold one or more number of cutters at a time and rotates at high speed to remove the metal at. On which the workpiece is clamped using T-slots.

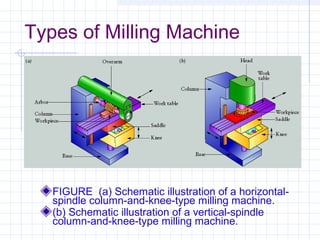

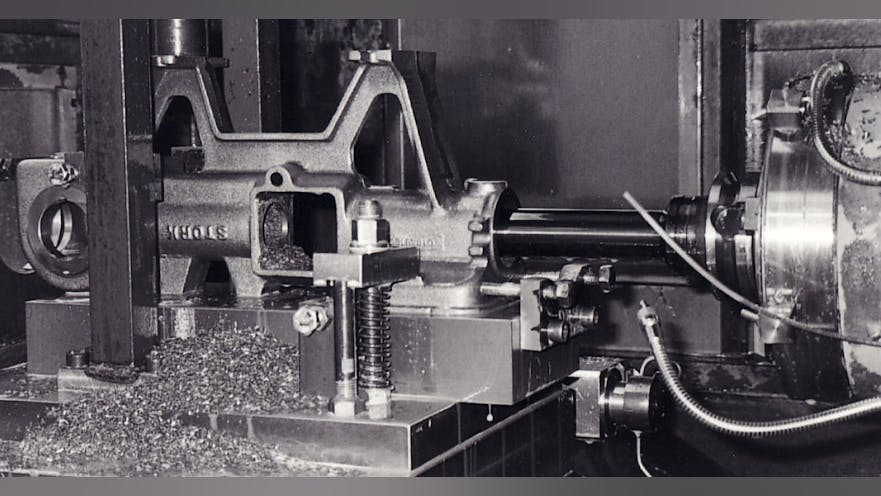

219 Milling machine cutter and work-piece position Milling machine cutter and workpiece position The milling is a process of metal-removing by feeding the workpiece passes through the rotating multipoint cutter. Column and base provide supports for the other parts of a milling machine. So let discuss all of these parts in detail.

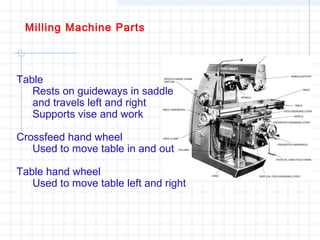

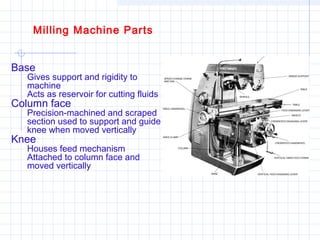

The milling machine component is used to fastened arbor support. The table moves longitudinally relative to the saddle. The Milling Machine consists of Base Column Knee Saddle Table Over-Arm Spindle or Arbor Arbor supports Ram and Milling Head.

THE MILLING MACHINE PREPARED BY. Which forms the foundation of machine on which other parts are mounted. Radial Milling Machine Manufacturer - Tengzhou ROOY CNC Machine Co is a machine tool manufacturing company that has gained global recognition in design and production of machine tools such as milling drilling lathe power presses and other machine tools for metal forming processes.

PPT Milling Machines PowerPoint presentation free to view - id. It may consist of one or two cylindrical bars that slide through the. Here in this Milling machine diagram you can easily see Its parts.

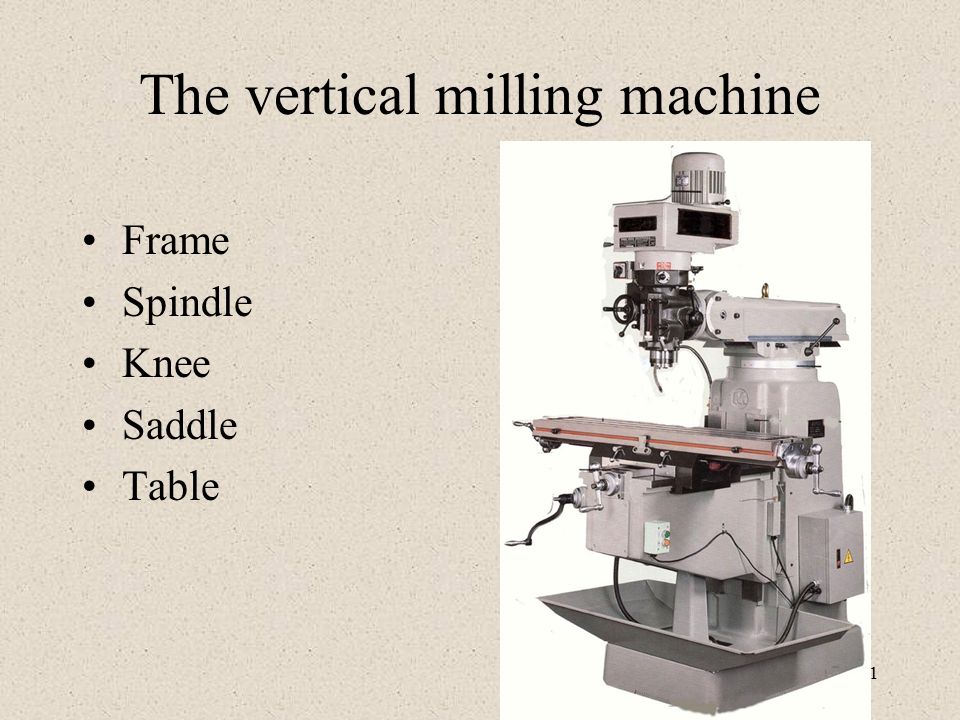

The milling head is the upper part of a vertical mill machine. The milling machine consists basically of a motor driven spindle which mounts and revolves the milling cutter and a reciprocating. The milling machine is excellent for forming flat surfaces cutting dovetails and keyways forming and fluting milling cutters and reamers cutting gears and so forth.

Column and Base Knee Saddle and Swivel Table Power Feed Mechanism Table Spindle Over Arm Overhanging Arm Arbor Support and Ram. The column. It is generally used to produce slot or groove in work pieces.

The knee is moved downward. This machine can also be used for cutting keyways racks and gears and for fluting taps and reamers. The base carries the column at its one end.

We will study one by one in detail. Differences between horizontal vertical milling machines sl. Milling is the process of removing metal by feeding the work past a rotating multipoint cutter.

The working of milling machine is as follow. The milling machine is used for making various types of gears. MILLING MACHINE OPERATIONS The milling machine removes metal with a revolving cutting tool called a milling cutter.

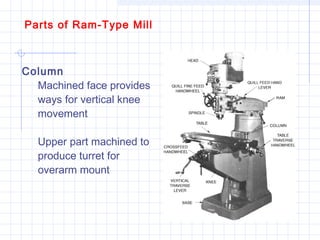

The electric energy from the outlet is converted into motion and the motion will spin the cutting tools. Column including base is the main casting that supports all other parts of milling machine. Supports the table and can move in the transverse direction.

Base Column Saddle Table Overhanging arm Front brace Spindle Arbor Base The base of the machine is grey iron casting and serves as a foundation member for all other parts which rests on it. Horizontal milling machine vertical milling machine 01 spindle is. The turning tool has of several cutting edges.

The diagram of cutting operation is shown below. The milling machine part can move transversely in and out on the column by a hand level. Provide the foundation of the machine.

Milling Machines Session 13 Vertical Milling Machine Developed in 1860s Combines vertical spindle of drill press with longitudinal and traverse movements of milling. The column rests on the base and base contains coolant reservoir and a pump which is used during machining operation that requires coolant. We compile them from the top to the bottom as the following.

1base 2column 3spindle 4spindle head 5knee 6saddle 7worktable 23. Milling Machines The basic components of these machines are as follows. The milling machine removes metal with a revolving cutting tool called a milling cutter.

Vertical milling machine major parts. With various attachments milling machines can be used for boring slotting circular milling dividing and drilling. The column rests on the base and also it has a coolant reservoir and a pump to provide coolant in machining operations.

Thus the jobs are machined at a faster rate than with single point tools and the surface finish is. It is used in industries to produce complex shapes. All the controlling points are set to zero like knee position saddle position etc.

In milling operation the rate of metal removal is rapid as the cutter rotates at a high speed and has many cutting edges. MILLING is the process of machining flat curved or irregular surfaces by feeding the workpiece against a rotating cutter containing a number of cutting edges. There is an oil reservoir and pump in the column to lubricate the spindle.

It can able to machine flat surface and irregular surfaces too. The company has been in existence for more than a decade and has endeavored to. Column houses main drive transmission system spindle.

Contains the reservoir and the pump which circulate the fluid to the cutting area. The main parts of the milling machine The main parts of the milling machine Column and Base. Now the work piece is clamped on the table by using clamping screw.

Parts of Milling Machine Following are the different parts of milling machine. Contains the spindle The base. Column and base provide support for the other parts of the milling machine.

Many special operations can be performed with the attachments available for milling machine usethe knee is. These are some important parts of a benchtop milling machine that you need to know. First the cutting tool is set at the arbor which is connected to the spindle.

It is the foundation. Horizontal Milling Machine. A milling machine consists of the following parts.

Save Save Milling machineppt For Later. The components of milling machine include. 100 3 100 found this document useful 3 votes 520 views 35 pages.

Motor The source of energy.

Introduction To Milling Machines

Introduction To Milling Machines

Introduction To Milling Machines

How Automatic Pallet Changers Enhance Cnc Machine Production Hwacheon Asia Pacific Pte Ltd

Customized Functions Different Occupies Seating Modular Breges System Ligita Levels Public Space Public Seating Modular Furniture Furniture Design

Cutting Tool Applications Chapter 10 Boring Operations And Machines American Machinist

Cnc Machining Vs Conventional Machining Emc Precision

Getting Concept To Car Faster Fast Cars Concept Cnc Training

Introduction To Milling Machines

Machine Tool Basic Machine Tools Britannica

The Vertical Milling Machine Ppt Download

What Is Milling Machine Operation Parts And Types Mechanical Booster

Milling Machine Parts Types Operations Milling Cutter Pdf

Simple Indexing In Milling Machine

Purchasing Procurement Process Flow Chart Process Flow Chart Process Flow Flow Chart

Arc Welding Amperage Settings According To Electrode Size And Metal Thickness Arc Welding Welding Electrodes

What Is Milling Machine Operation Parts And Types Mechanical Booster

Strimmer Trimmer Chainsaw Saw Cutter Carb Carburettor For 43 49cc Engine Wish Carburetor Chainsaw Trimmers